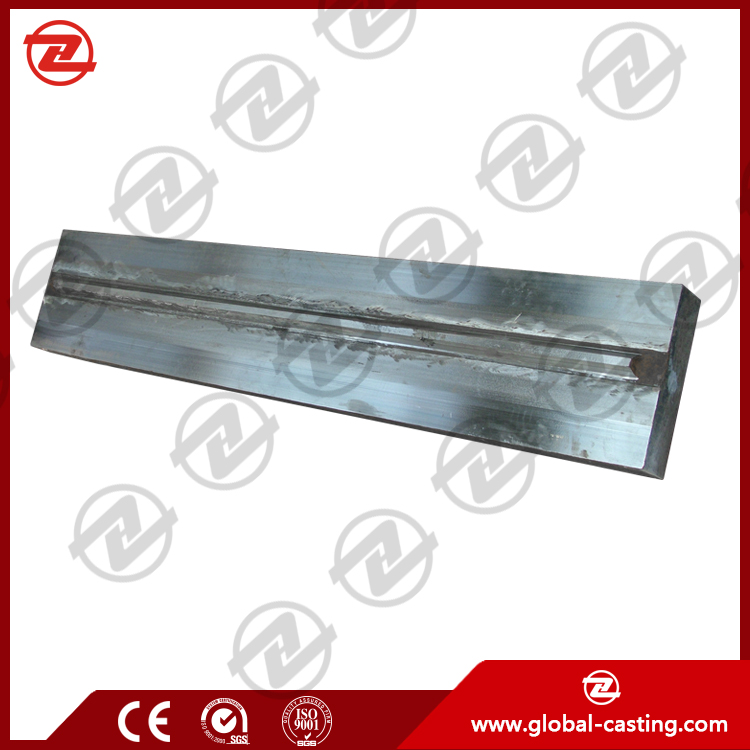

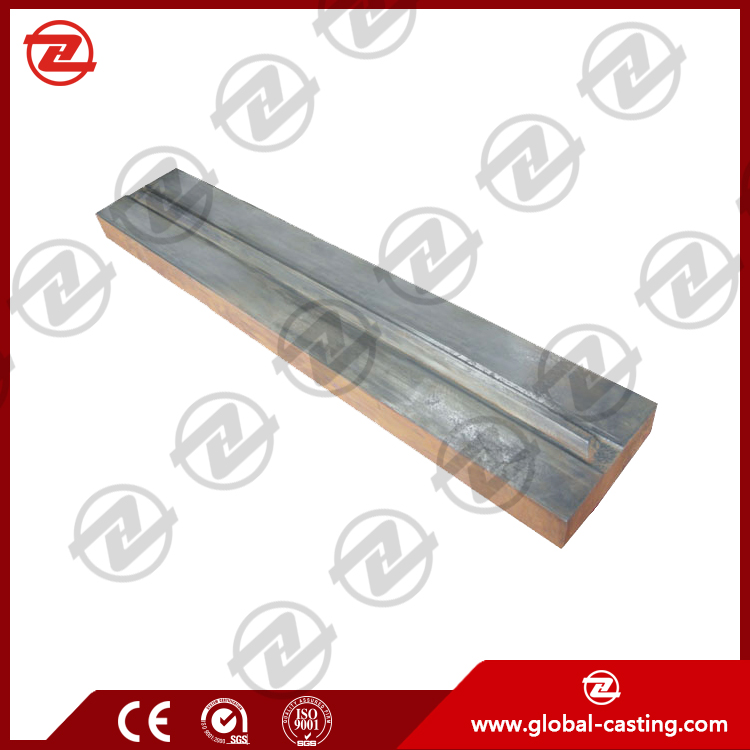

High Manganese Blow Bar

Commodity score:

| Brand | Zhili |

| Place of Origin | Henan, China (Mainland) |

| Type | manganese steel flat bar |

| Material | High Manganese Steel... |

| Name | manganese steel flat bar |

| Heat treatment | Anneal,quenching ,tempering |

| Machine Type | Crusher |

| Processing Type | Casting |

| Certification | BV certificate ,ISO2008 |

| Hardness | 179-229HB |

Quick Details

| Place of Origin: | Henan, China (Mainland) |

| Type: | manganese steel flat bar |

| Material: | High Manganese Steel... |

| Name: | manganese steel flat bar |

| Heat treatment: | Anneal,quenching ,tempering |

| Physical prope: | Impact hardness |

| Brand Name: | ZHILI |

| Machine Type: | Crusher |

| Processing Typ: | Casting |

| Other name: | high manganese steel flat bar |

| Guarantee: | One year against quality.. |

| Chemical control: | Spectrum analyzer |

| Model Number: | LYZL |

| Certification: | BV certificate ,ISO2008 |

| Use: | Ore Mining |

| Hardness: | 179-229HB |

| Application: | Cement plant ,quarry ,power.. |

| Quality tester: | Ultrasonic fault detector |

Packaging & Delivery

| Packaging Details: | Package of manganese steel flat bar: |

| 1.Industrial packaging :Plastics tube+ carton+ wooden pallets | |

| 2.Commercial packing:Plastic bag+ color box+ wooden pallets | |

| 3.Transportation: Air/shipping/Railway | |

| 4.As the clients'requirement | |

| Delivery Detail: | Shipped in 30 days after payment |

Product Description

Introduction of manganese cement plant blow bars crusher blow bars :

Blow bar is the main spare part of impact crusher. There are high manganese blow bar,high chrome blow bar. The material depends on the requirement of the crush material. If the material needs strong impact toughness, the high manganese blow bars are ideal selection. If we need high wear-resisting of blow bar, the chrome blow bar are our first choice.

Description of manganese cement plant blow bars crusher blow bars :

High manganese blow bar: while casting, we not only add molybdenum, vanadium, titanium, nickel, boron and other rare alloy elements. Meantime, we specially adopt variety of alloy modifier to strengthen the matrix. Those blow bars use refining, vacuum casting, directional solid and etc technical’s to increase the grain refinement and make the hammers performance achieve the best performance. Our blow bars have successfully replaced the counter-attacking large Blow Bars of Germany Krupp, Blow Bars of Germany Aubema, counter-attacking Blow Bars of Germany Hazemag and make them nationalization.

Specification of manganesecement plant blow bars crusher blow bars :

1)Suit Filed: Cement, mining, quarry, power and metallurgy companies.

2)Molding: Molding--Modeling-Casting-Cleaning-Water treatment-Machining

3)Certification: ISO9001:2000/ BV/ China Patent No. 200810049101.2

High manganese blow bars usually have high weight and the drawing is complex, especially when the bimetal composite and insert casting can’t solve the matrix wear resistance, we use high manganese blow bars.

| Blow Bar Chemical Component | |||||||

|---|---|---|---|---|---|---|---|

| Material | c | Mn | Cr | Si | Mo | Ni | Cu |

| Mn13Cr2 | 1.1~1.4 | 12~15 | 1.7~2.2 | 0.3~1.0 | ---- | ---- | ---- |

| Mn18Cr2 | 1.1~1.4 | 17~19 | 1.8~2.2 | 0.3~1.0 | ---- | ---- | ---- |

Details of manganese cement blow bars crusher blow bars:

High manganese blow bars usually have high weight and the drawing is complex, especially when the bimetal composite and insert casting can’t solve the matrix wear resistance, we use high manganese blow bars.

Emply the external refining technology effectively reduced the harmful elements, impurity and oxygen and hydrogen harm, greatly enhanced the abrasion resistance and impact toughness of the steel.

Using proprietary metamorphic agent for modification treatment, fine grains, improves carbide configuration and distribution, and to improves the abrasion resistance and tenacity.

Optimizing heat treatment process, make the product of uniform hardness especially, impact abrasion resistance becoming stronger