Bimetallic Composite Hammer

Commodity score:

| Brand | Zhili |

| Place of Origin | Henan, China (Mainland) |

| Application | ore mining |

| certification | ISO9001:2000/BV certificate |

| application | cement plant, quarry, power.. |

| wanrranty | one year |

| Material | Iron |

| hardness | 35-65HRC |

| Dimensions | Standard |

| quality tester | ultrasonic fault detector |

Quick Details

| Place of Origin: | Henan, China (Mainland) |

| Application: | ore mining |

| certification: | ISO9001:2000/BV certificate |

| application: | cement plant, quarry, power.. |

| wanrranty: | one year |

| chemical contr.: | spectrum tester |

| Brand Name: | metso, terex, sanbao,etc. |

| Material: | Iron |

| material: | high manganese steel/high.. |

| hardness: | 35-65HRC |

| dimension: | according to drawings |

| Model Number: | depends |

| Dimensions: | Standard |

| usage: | coal/ore mining |

| heat treatment: | annealing, quenching, temper.. |

| quality tester: | ultrasonic fault detector |

Packaging & Delivery

| Packaging Details: | wooden package, seaworthy, according to customer's requirement |

| Delivery Detail: | 35days after payment |

Product Description

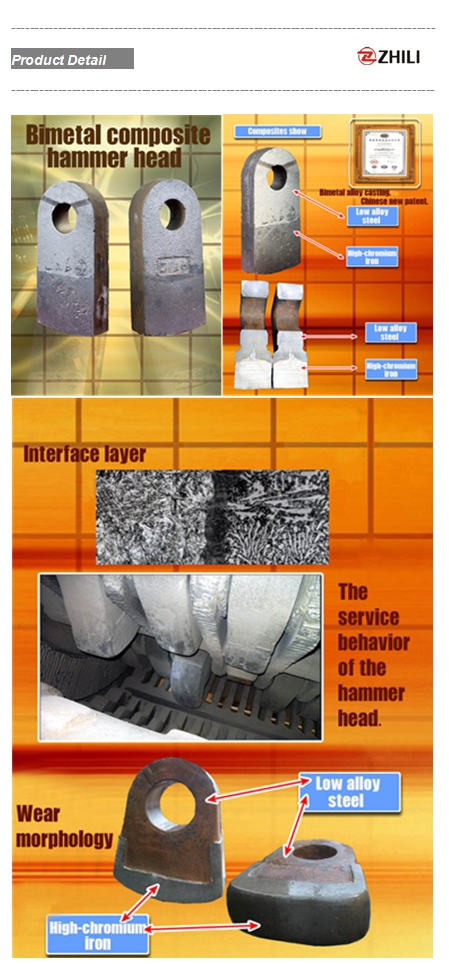

Feature of bimetallic composite:

Our patent products with independent research and development (China Patent No. 200810049101.2) --- Bimetal thermal-composite material.

Bi-metal composite materials: working lifetime up to 2-3 times of traditional single material, especially used in large ball mill liner.

It is our patent products with independent research and development (China Patent No. 200810049101.2) --- Bi-metal thermal-composite material.

This product adopts special technology and professional process to combine two materials with different performance into a whole one under molten condition. The interface of combining is up to 100%.

The hardness of bi-metal thermal composite material is up to HRC62-65.

Its impact ductility is over (AK) 30J/cm2.

It has high anti-friction effects and safe reliability.

It is especially used to produce hammers and board hammers used in large crushers, liners used in large ball mill crushers. Effects can be more remarkable when it is used in harsh environment, other crushing conditions like limestone, cement clinker, sand stone, coal spoil, basalt etc.

| Chemical Component Ratio(%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Working part | Hammer Body | ||||||||

| C | Mn | Cr | Mo | Ni | Cu | Si | C | Mn | Si |

| 2.0~3.3 | 0.8~1.2 | 18~22 | ≥0.8 | 0.4~0.6 | 0.8~1.2 | ≤0.8 | 0.33~0.36 | 0.60~0.80 | 0.4~0.5 |

| Chemical Component | |||||||

|---|---|---|---|---|---|---|---|

| Material | C | Mn | Cr | Si | Mo | Ni | Cu |

| Mn13Cr2 | 1.1~1.4 | 12~15 | 1.7~2.2 | 0.3~1.0 | |||

| Mn18Cr2 | 1.1~1.4 | 17~19 | 1.8~2.2 | 0.3~1.0 | |||

| Cr12 | 2.0~3.3 | ≤2.0 | 11~14 | ≤1.2 | ≤3.0 | ≤2.5 | ≤1.2 |

| Cr15 | 2.0~3.3 | ≤2.0 | 11~14 | ≤1.2 | ≤3.0 | ≤2.5 | ≤1.2 |

| Cr20 | 2.0~3.3 | ≤2.0 | 14~18 | ≤1.2 | ≤3.0 | ≤2.5 | ≤1.2 |

| Cr26 | 2.0~3.3 | ≤2.0 | 23~30 | ≤1.2 | ≤3.0 | ≤2.5 | ≤2 |