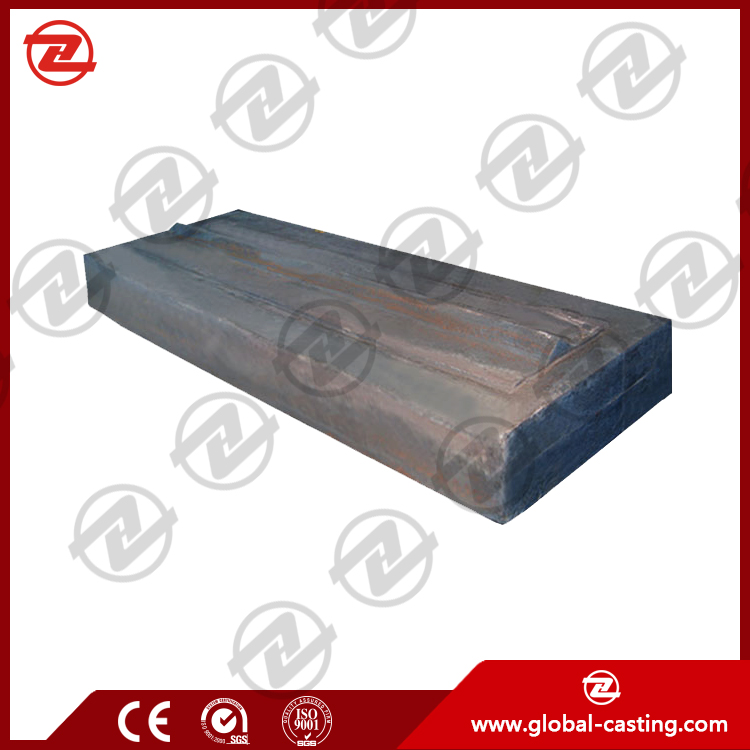

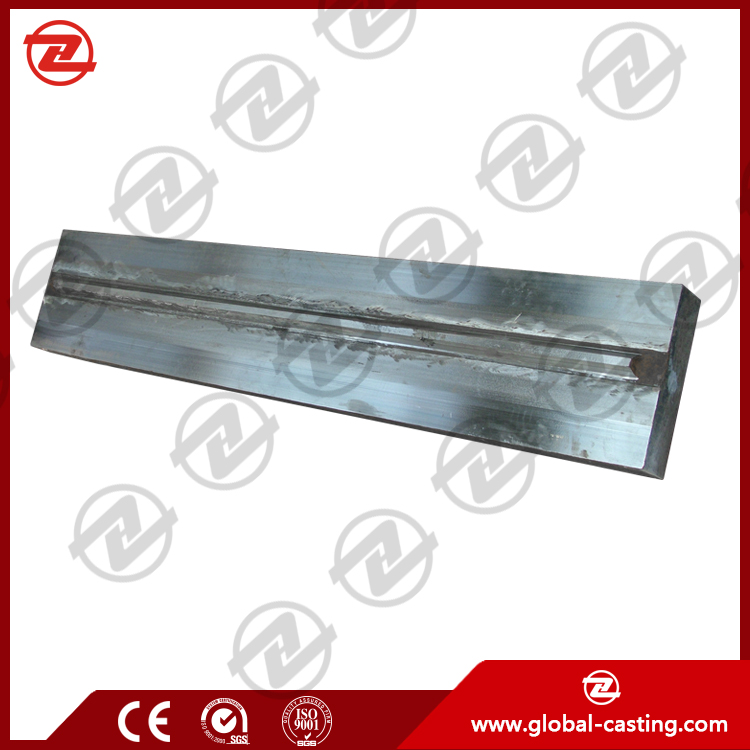

High Chrome Blow Bar

Commodity score:

| Brand | ZHILI High Chrome Blow Bar |

| Brand Name | ZHILI |

| Processing Type | Casting |

| Guarantee | One year against quality defects |

| Chemical control | Spectrum analyzer |

| Quality tester | Ultrasonic fault detector |

| Application | Cement plant ,quarry ,power plants, |

| Certification | BV certificate ,ISO2008 |

| Heat treatment | Anneal,quenching ,tempering |

| Hardness | More than 58-65HRC |

Quick Details

| Place of Origin: | Henan, China (Mainland) |

| Type: | high chrome Blow Bar |

| Material: | Chromium, High chrome |

| Name: | hammer crusher parts |

| Heat treatment: | Anneal,quenching ,tempering |

| Physical prope: | Anti-wear |

| Brand Name: | ZHILI |

| Machine Type: | Crusher |

| Processing Typ: | Casting |

| Other name: | crusher hammer parts |

| Guarantee: | One year against quality.. |

| Chemical control: | Spectrum tester(analyser) |

| Model Number: | LYZL- hammer crusher part |

| Certification: | BV certificate ,ISO2008 |

| Use: | Ore Mining |

| Hardness: | More than 57-62HRC |

| Application: | Cement plant ,quarry ,power.. |

| Quality tester: | Ultrasonic fault detector |

Packaging & Delivery

| Packaging Details: | Package of hammer crusher parts: |

| 1.Industrial packaging :Plastics tube+ carton+ wooden pallets | |

| 2.Commercial packing:Plastic bag+ color box+ wooden pallets | |

| 3.Transportation: Air/shipping/Railway | |

| 4.As the clients'requirement | |

| Delivery Detail: | About 35 days after the deposit |

Product Description

The high chrome blow bar especially suit for hard rock crushing with high efficiency and energy saving, the discharge material size is smaller, and shape more equal. We can special produce according to requirement. (OEM produce)

Technical parameters

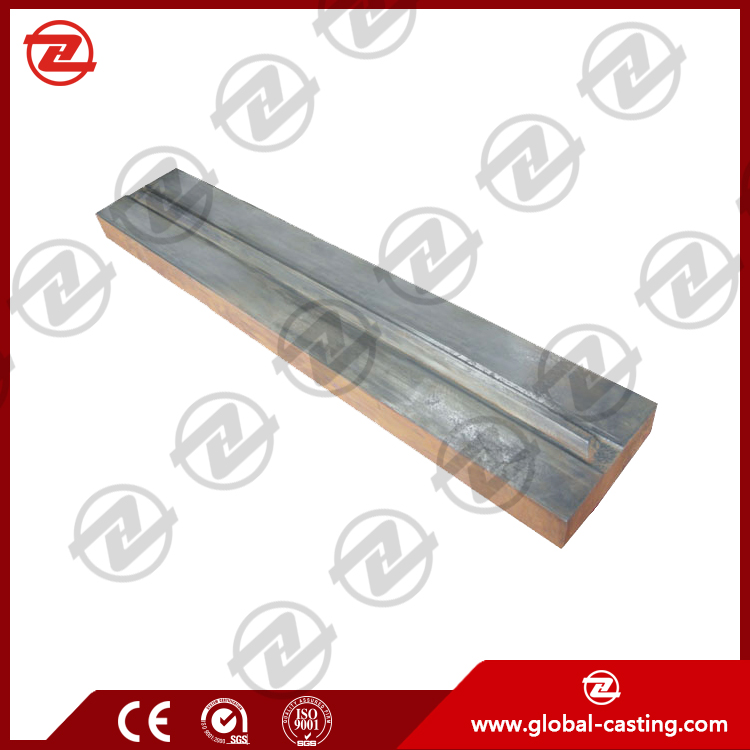

| Material |

Cr15Mn2,Cr20Mn2,Cr26Mn2 |

| Control | Spectrometer chemical analysis and control while producing |

| Molding Process | Water-glass sand casting or lost form casting |

| Melting facility | Medium frequency electric furnace |

| Heat Treatment | Anneal, quenching, tempering |

| Quality Guarantee | One year against manufacturing defeat |

| Testing | Hardness, flaw detector test |

| Certificate | ISO9001~2008 Passed; BUREAU VERITAS |

High chrome blow bar: while casting, we not only add molybdenum, vanadium, titanium, nickel, boron and other rare alloy elements. Meantime, we specially adopt variety of alloy modifier to strengthen the matrix. Those blow bars use refining, vacuum casting, directional solid and etc technical’s’ to increase the grain refinement and make the hammers performance achieve the best performance.

|

Material |

C |

Cr |

Mn |

Si |

S |

p |

|

Cr15 |

2.8~3.2 |

13~15 |

≤2 |

≤1.2 |

≤0.06 |

≤0.06 |

|

Cr20 |

2.8~3.2 |

18~22 |

≤2 |

≤1.2 |

≤0.06 |

≤0.06 |

|

Cr26 |

2.8~3.2 |

24~26 |

≤2 |

≤1.2 |

≤0.06 |

≤0.06 |